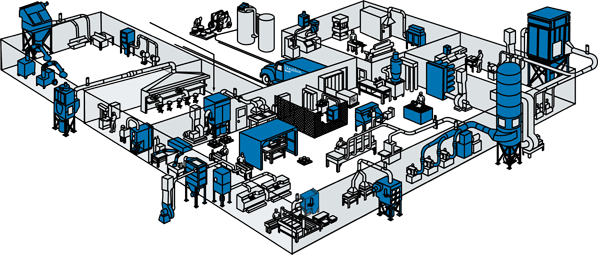

MANUFACTURING SECTOR

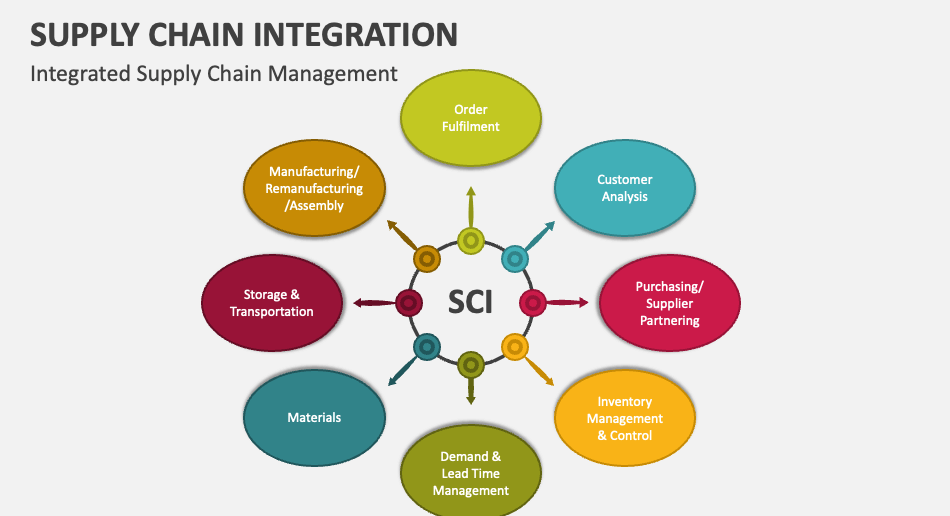

The manufacturing sector is a cornerstone of industrial economies, encompassing production processes, supply chain management, and product innovation. Expanding manufacturing operations internationally requires optimizing production efficiency, ensuring quality control, and navigating regulatory landscapes. SKY Excelerate provides comprehensive support to manufacturing companies aiming to scale their operations globally.